【RENEO】大族锂电智能装备:为新能源电池智能制造提供整体解决方案

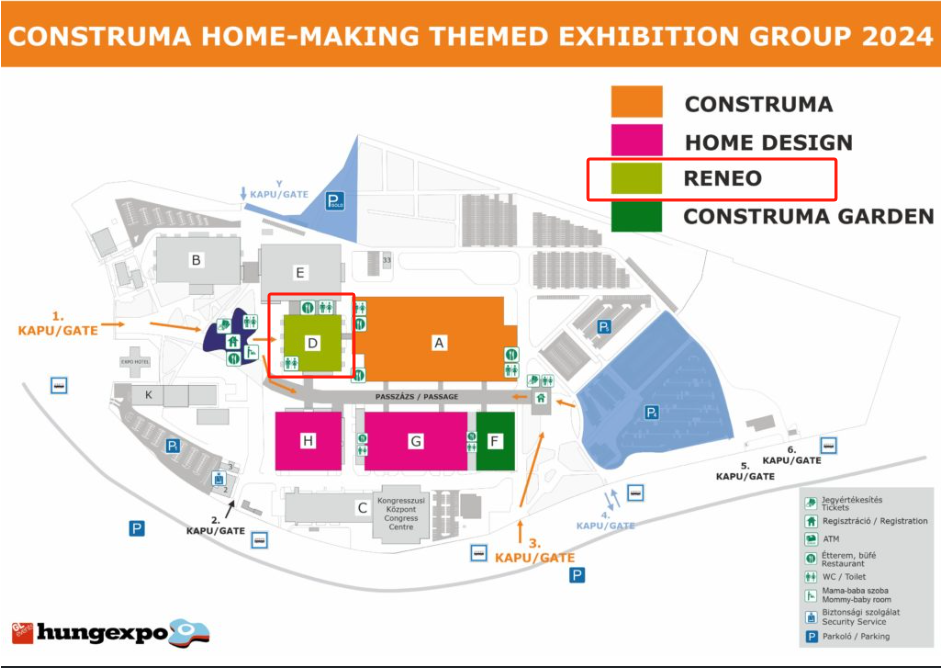

匈牙利最大最专业的能源展——

2024年匈牙利国际可再生能源展

即将拉开大幕

匈牙利国际可再生能源展(RENEO)是匈牙利最大最专业的能源展,已成功举办了10届。展会专注于绿色科技、环保和可再生能源的应用,展出内容包括可再生能源(储能、电池、氢能、光伏、材料、设备、配套装备)、节能(节能技术、能源使用量计量系统、节能系统)等,将全面呈现前沿环保解决方案和绿色理念。

01、大族锂电智能装备(HAN'S-SLE)

Shenzhen Han's Lithium Battery Smart Equipment Co., Ltd. was established in 2018. It is a holding subsidiary of Han's Laser Technology Industry Group Co., Ltd. The company has more than 4,000 employees, 40% of whom are R&D technical talents. Specializing in the research, development, production and sales of lithium batteries, hydrogen fuel cells, solid-state batteries and other battery energy storage components and related equipment. Han's Lithium Smart Equipment has the comprehensive strength to integrate the entire line of lithium batteries and can provide "turnkey projects" for global customers. At present, the company has three R&D centers in Shenzhen, Wuhan, and Chengdu, five production bases in Shenzhen, Yibin, Jingmen, Changzhou, and Guangzhou, Han's Lithium Smart Equipment adheres to the "customer-centered" business philosophy.

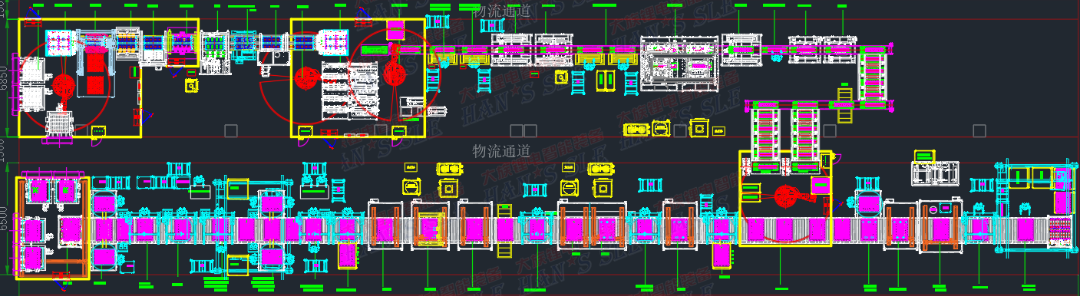

Han's SLE provides electrode making, cell making, testing and assembly equipment for the battery production process. The main products are including rolling, die cutting, slitting, winding/stacking, cell assembling, baking, electrolyte injection, formation and grading, blue tape wrapping, module and PACK assembling series products, and special equipment for the battery manufacturing industry, such as rolling and slitting integrated machine, die cutting and slitting machine, die cutting and winding machine, laser cutting, stacking and hot-pressing machine, laser tab forming and cross-cutting machine.Han’s SLE is fully capable of providing customers with integrated smart factory solutions.

02、辊压分切一体机 Calendering and Slitting Integrated Machine

该设备用于将涂布后成卷宽幅电池极片展开、经过连续液压对辊装置,将极片厚度均匀辊压,辊压后的极片经过在线激光测厚设备进行厚度扫描测量,液压对辊压力可根据极片设定厚度和扫描测量自动调整,直至极片满足工艺要求值;达标后再经过分切机,将极片分切成等宽的多条极片,同时配置风刀、毛刷、超声波除尘等方式,保证极片洁净度,采用CCD对极片宽度尺寸进行检测,检测后的极片尺寸与分切前行进纠偏形成闭环控制,保障分切精度,然后收成整齐卷料。

This equipment unwinds the coated wide electrode rolls, and calenders the electrodes evenly through the continuous hydraulic roller device. Online laser thickness measuring device scans and measures the thickness of the calendered electrode, the hydraulic calendering pressure is automatically adjusted according to the set electrode thickness and the measured thickness until the electrode thickness reaches the required value, and then, the electrode is transferred to the slitting machine and cut into multiple pieces of equal width. Air knifes, hairbrushes and ultrasonic dust removal device are equipped to keep electrodes clean. CCD is used to inspect the width size of electrodes. The inspected electrode size and the deviation correction before slitting can form a closed-loop control to ensure the slitting accuracy. Finally, the slit electrodes are rewound into neat rolls.

该设备用于动力电池极片极耳成型和分条,采用双工位自动放卷接带的方式,全程多段张力控制,三级纠偏控制,保证极片激光切割和分切精度的尺寸,同时配置风刀、毛刷、超声波除尘等方式,保证极片洁净度,采用CCD对极片表面缺陷和极耳尺寸进行检测,检测后的极片尺寸与模切前和分切前行进纠偏形成闭环控制,配备打标机对NG极片进行贴标,最后经由收卷张力控制收成卷料,自动换卷。

This equipment is used for tab forming and slitting of power batteries. It adopts dual-station automatic roll unwinding and connecting, with multi-section tension control and three-level deviation correction control in the whole process, to ensure the laser cutting and slitting accuracy. Air knifes, hairbrushes and ultrasonic dust removal device are equipped to keep electrodes clean. CCD is used to detect the electrode surface defect and tab size. The detected electrode size and the deviation correction before die-cutting and slitting can form a closed-loop control, and NG electrodes will be labeled by the marker, and the processed electrodes are rewound into rolls, with automatic roll change.

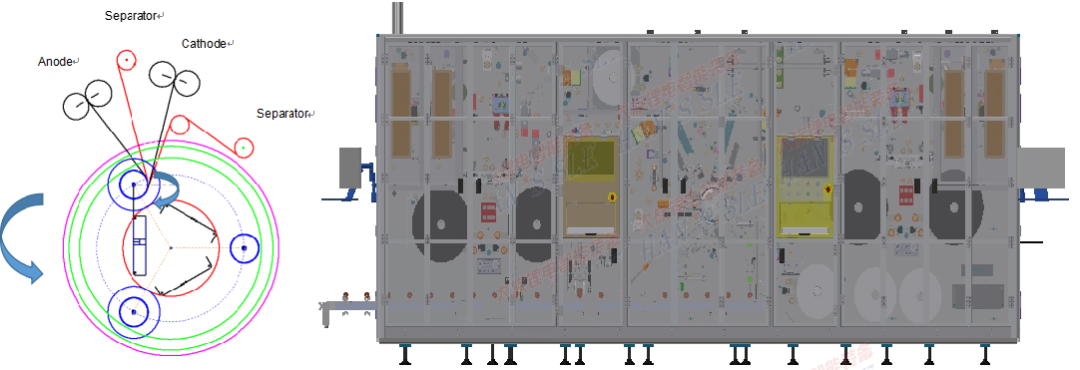

本设备用于圆柱锂离子电池模切及卷绕工序,为全自动运行设备。工作流程如下:两卷隔膜主动放卷并纠偏,经过隔膜张力、测长、除静电、除铁后引入卷绕部位,正、负极片主动放卷并纠偏后经放卷张力机构、极耳激光模切、除尘、极片贴胶、卷绕张力、测长、行进纠偏、导入机构、裁断机构、引入卷绕部位;极片与隔膜隔叠并按工艺要求进行卷绕,贴收尾胶带,反转扩孔,成品自动下料;可对接带、单卷、等不良品分类剔除,卷绕合格电芯放入皮带线,并对其进行烫孔、测圆度、极耳对齐度检测、外观检测,扫码;极片极耳预折、卷绕极耳折弯、下料极耳拍平等多极耳电芯工序为可选模块,可兼容多种规格型号电芯生产;卷绕过程,稳定性好、噪音低;系统参数集中操控,人机界面采用触摸屏方式、分级控制,工艺参数可锁定、存储和调用。

This fully-automatic operating equipment is used for the die-cutting and winding of cylindrical li-ion batteries. The workflow is as follows: two separator rolls are automatically unwound and corrected, then, are led into the winding part after the separator tension mechanism, length measurement, electrostatic removal and iron removal. The positive and negative electrodes are automatically unwound and corrected, then, are led into the winding part after unwinding tension mechanism, tab laser die-cutting, dust removing, electrode taping, winding tension, length measuring, movement deviation correction, lead-in mechanism and cutting mechanism. Electrodes and separators are stacked alternately, and according to the process requirements, are wound, stuck with end tape, reamed, and unloaded as the finished product. NG products are sorted and removed. OK cells are placed on the conveyor belt, and hole opening, roundness measurement, tab alignment inspection, appearance inspection, and code scanning are performed. Such optional modules as tab pre-folding, winding tab bending and unloading tab flattening are available, compatible with the production of various specifications/models of cells. The winding process has good stability and low noise, the system parameters are centrally controlled, and the HMI adopts touch screen and hierarchical control. Process parameters can be locked, stored and called.

电芯中段装配段设备,可以覆盖从卷绕/叠片机下料到电芯烘烤前上料,和二次注液后电芯密封钉焊接和二次氦检、完成电芯中段各个工艺工序的生产,可以覆盖市场中各类型电芯工艺。

It is the middle-end assembly equipment of the cell manufacturing process, covering the process from winding/stacking machine unloading to loading before cell baking, and sealing pin welding and second helium test after the second filling, and can cover various types of cell processes in the market.

1.功率由1.2W/CM²降低至0.4W/ CM²,整体能耗降低50%,单线年节约电费30万美元

The power is reduced from 1.2W/CM² to 0.4W/ CM², the overall energy consumption is reduced by 50%, and the annual electricity cost of a single line is saved by 300,000 US dollars.

2.双重过滤控制,Particle防护率>30W级

Double filter control,Particle protection rate > 30W level

3.设备高柔性兼容性:方形铝壳、圆柱、软包、储能等多品种兼容性产品

Equipment high flexibility compatibility: square aluminum shell, cylinder, soft package, energy storage and other varieties of compatible products.

4.干燥调度系统稳定性及兼容性:全球已交付超500条/套

Drying scheduling system stability and compatibility: the world has delivered more than 500 pieces/sets.

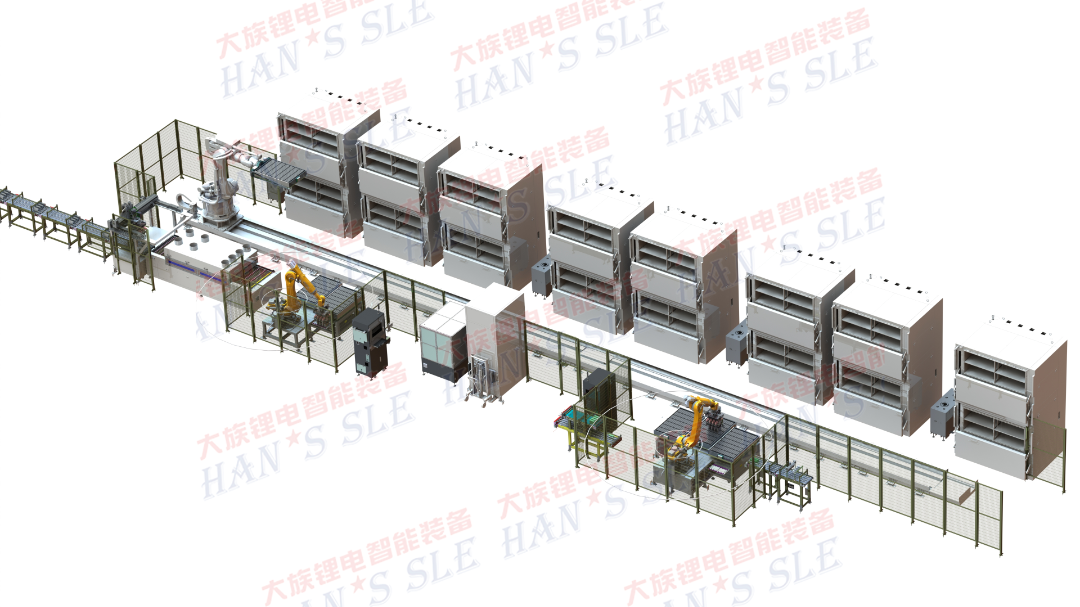

1.模组段主要包含:电芯大包装自动上料,扫码OCV检测,自动NG排料补料,等离子清洗,大面贴胶,贴胶检测,模组堆叠,模组加压,套钢带打PET带,极柱寻址,极柱激光清洗,连接片安装,BBS焊接,焊后视觉检测,EOL测试、DCIR测试;

Module line mainly includes: automatic cell feeding of large packaging, code scanning for OCV detection, automatic NG discharge and feeding, plasma cleaning, large surface tape sticking, glue testing, module stacking, module pressurization, steel belt PET belt, pole addressing, pole laser cleaning, connection piece installation, BBS welding, post-welding visual inspection, EOL test, DCIR test;

2.PACK段主要包含:液冷板上线,液冷板等离子清洗,液冷板涂胶及检测,模组自动入箱,极柱寻址,跨接铝排焊接及焊接检测,自动锁螺丝,镍片焊接,自动下线,及相应人工作业和测试等功能;

PACK line mainly includes: liquid cooling plate loading, liquid cooling plate plasma cleaning, liquid cooling plate coating and testing, module into box automatically, pole addressing, aluminum raw welding and welding inspection, automatic locking screw, nickel sheet welding, automatic unloading, and corresponding manual work and testing functions;

3.电芯信息、模组信息和设备生产参数会进行绑定,数据可存储本地或上传厂级MES,可快速追述及查询。

Cell information, module information and equipment production parameters will be bound, and the data can be stored locally or uploaded to factory-level MES, which can be quickly traced and queried.

1.设备主要包含:电芯上料输送,扫码OCV检测,电芯分档分选,大面贴胶,贴胶检测,模组堆叠,模组加压, 套钢带打PET带,极柱寻址,极柱激光清洗,连接片安装,BBS焊接,焊后视觉检测,EOL测试、DCIR测试、PACK装配输送线、PACK性能测试、吊装下线。

The equipment mainly includes: Cell loading and conveying, code scanning for OCV detection, cell sorting, large surface tape sticking, glue testing, module stacking, module pressurization, steel belt PET belt, pole addressing, pole laser cleaning, connection piece installation, BBS welding, post-welding visual inspection, EOL test, DCIR test, PACK assembly conveyor line, PACK performance test, lifting unloading.

2.电芯信息、模组信息和设备生产参数会进行绑定,数据可存储本地或上传厂级MES,可快速追述及查询。

Cell information, module information and equipment production parameters will be bound, and the data can be stored locally or uploaded to factory-level MES, which can be quickly traced and queried.

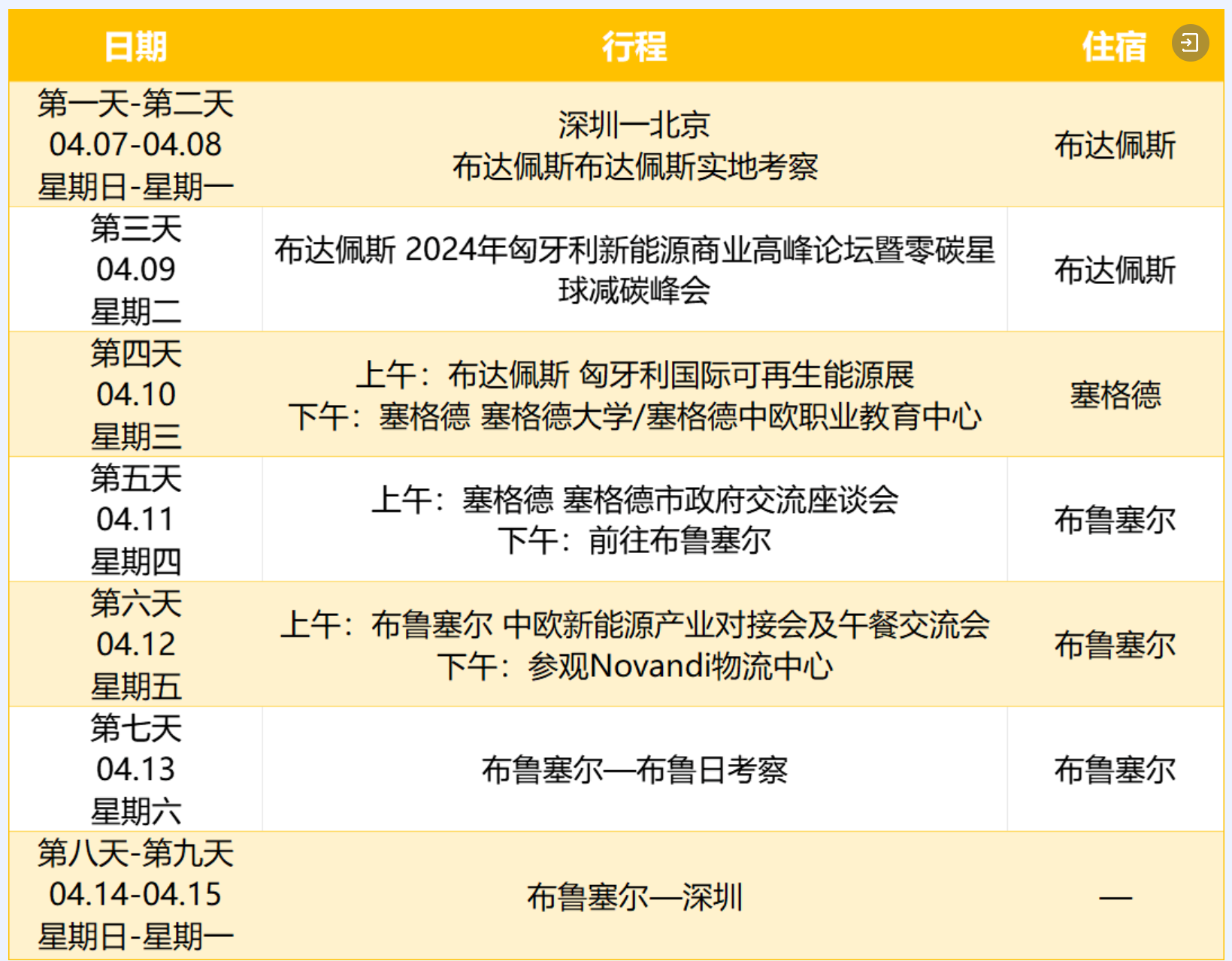

03、欧洲商务考察活动

➣行程安排表如下:

➣同期精彩活动:

04、报名及联络方式

有关欧洲商务考察活动具体事宜请联系:

钟女士 18033059905

欧阳女士13923776822

相关文章

- 锂源科技四川园区第二期项目开工仪式隆重举行

- 2021年12月动力电池产量共计31.6GWh,全年累计219.7GWh

- “中国锂电第一城”不是宁德,也不是新余,而是它!

- 磷酸铁锂电池项目不再要求180Wh/kg!锂离子电池行业规范条件(2021年本)发布

- 总投资70亿元 欣旺达、川恒股份与贵州省瓮安县人民政府签署战略合作协议

- 北交所开市:900亿 市值一哥“贝特瑞”

- 10个方面31项具体举措!《为“专精特新”中小企业办实事清单》正式印发

- 吉阳智能“电池制造工艺与装备院士工作站”正式挂牌

- 吉阳智能承办"数字化车间集成国家标准启动会"成功召开

- 工信部:引导锂离子电池企业减少单纯扩大产能的制造项目,锂离子电池行业规范条件(2021 年本)开始征求意见!